Key data

|

Dimensions |

14 x 7 x 3.1 meter |

|

Construction year |

2018 |

|

Rinse tank |

490 x 2000 x 955 mm |

|

Capacity |

process related |

Customer

Stalder AG

ClientStalder AG

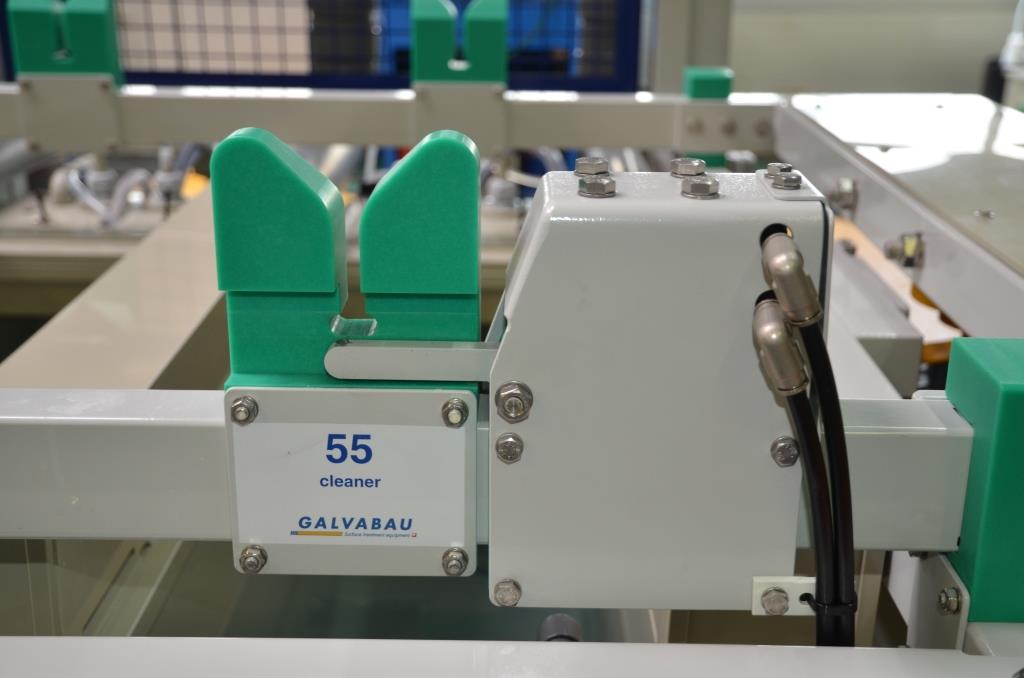

ProjectAnodisier- & Färbeautomat