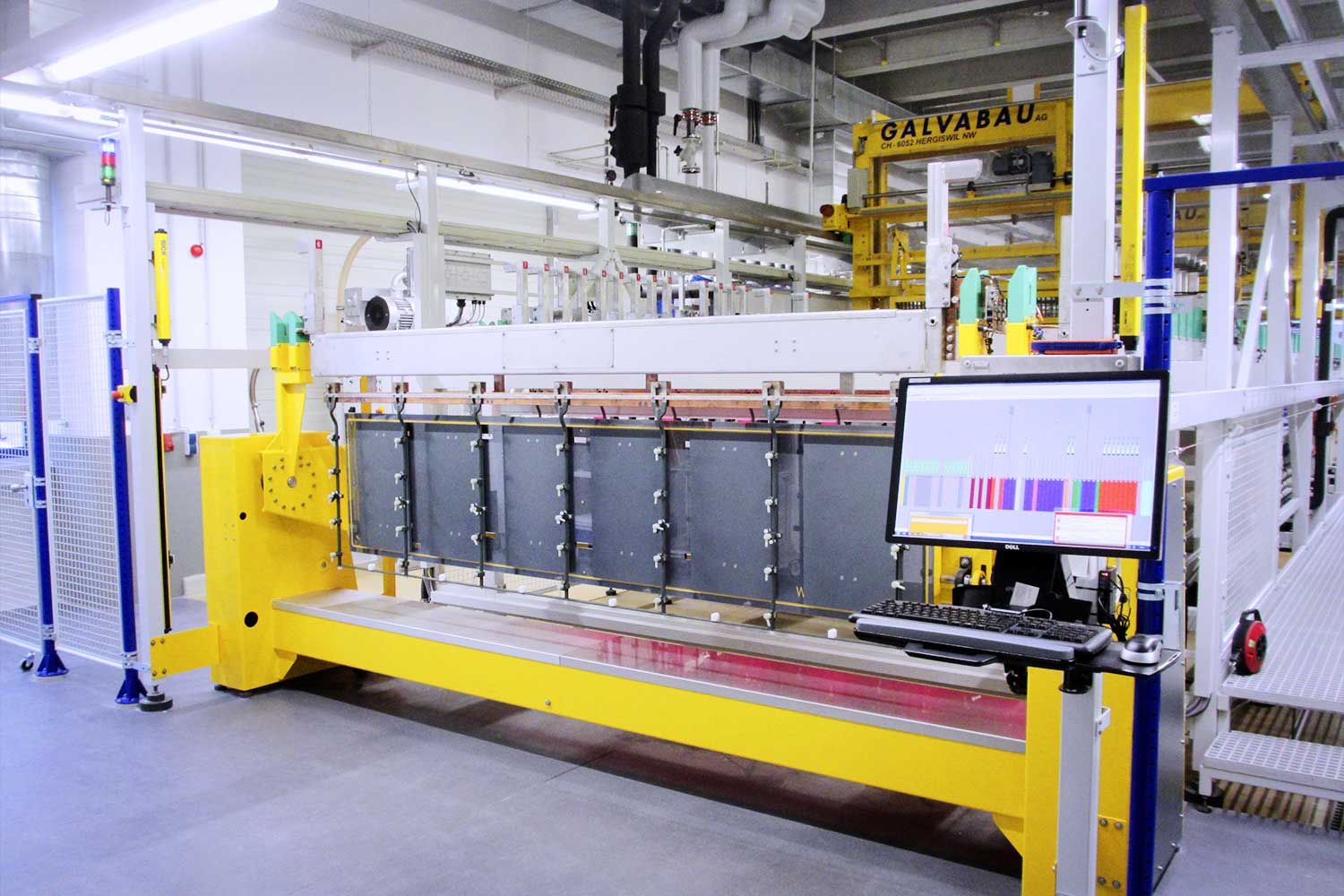

Key data

|

space requirements |

30,6 x 4,3 x 5,7 meter |

|

construction year |

2015 |

|

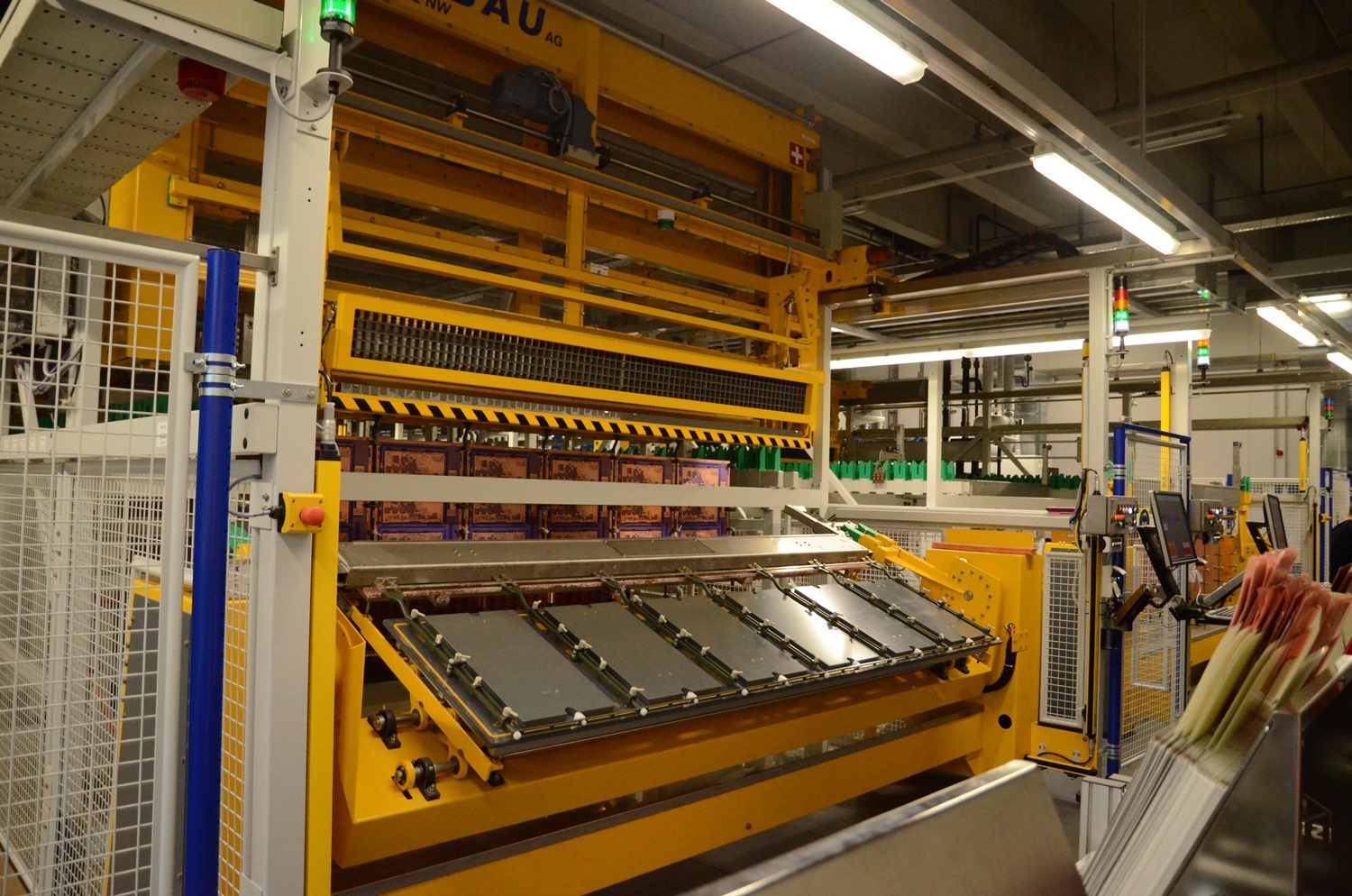

inside dimensions ( rinsing-tank) |

210 x 3200 x 900 mm |

|

capacity |

cycle time 13,2 min → 7,7 m²/h |

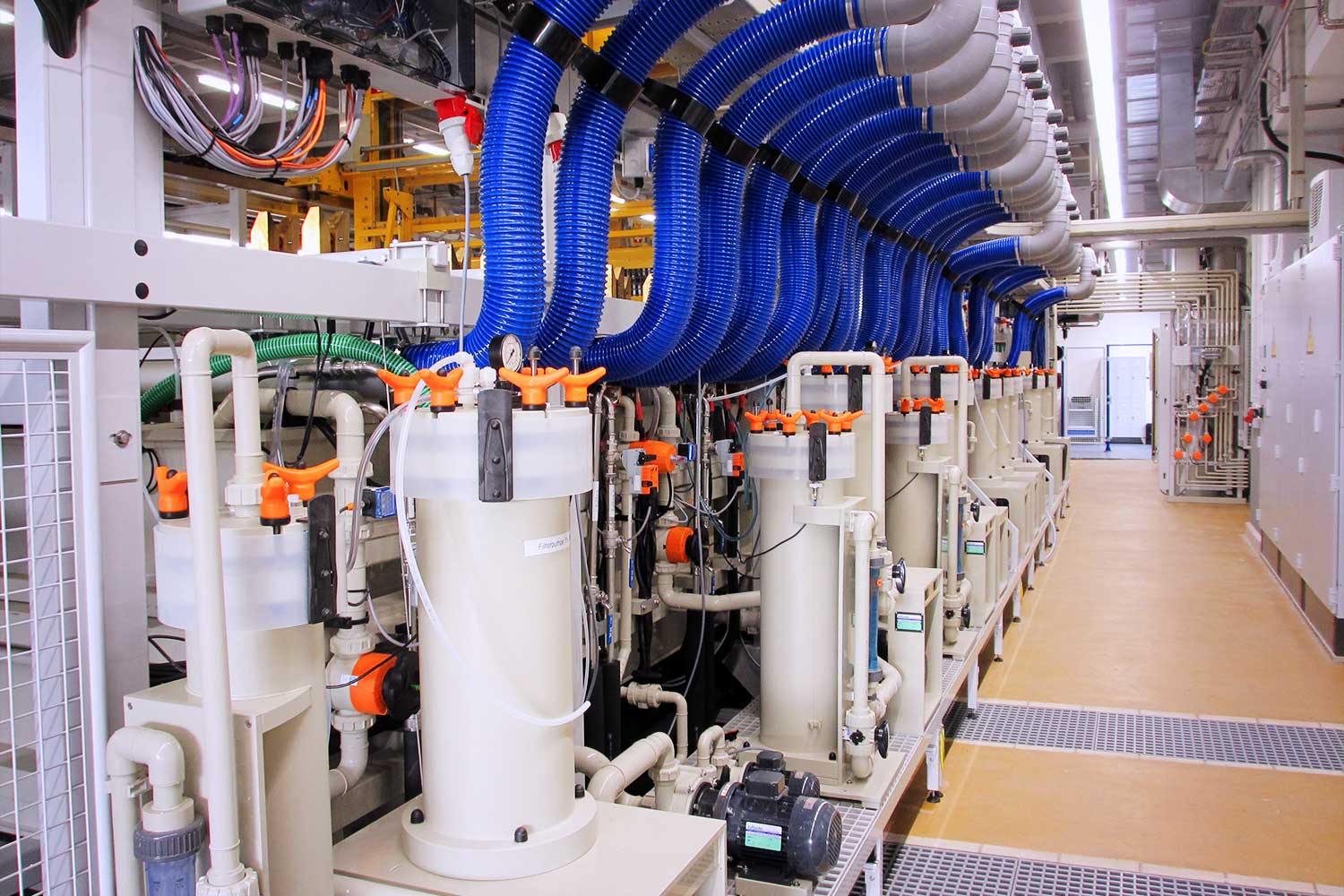

ProjectVollautomatische Anlage für die Herstellung von Leiterplatten (Leiterbildaufbau))