Key data

|

space requirements |

25,3 x 8,5 x 4,5 Meter |

|

construction year |

2013 |

|

inside dimensions (rinsing tank) |

210 x 2250 x 900 mm |

|

capacity |

Taktzeit 7,7 min → 7,3 m²/h |

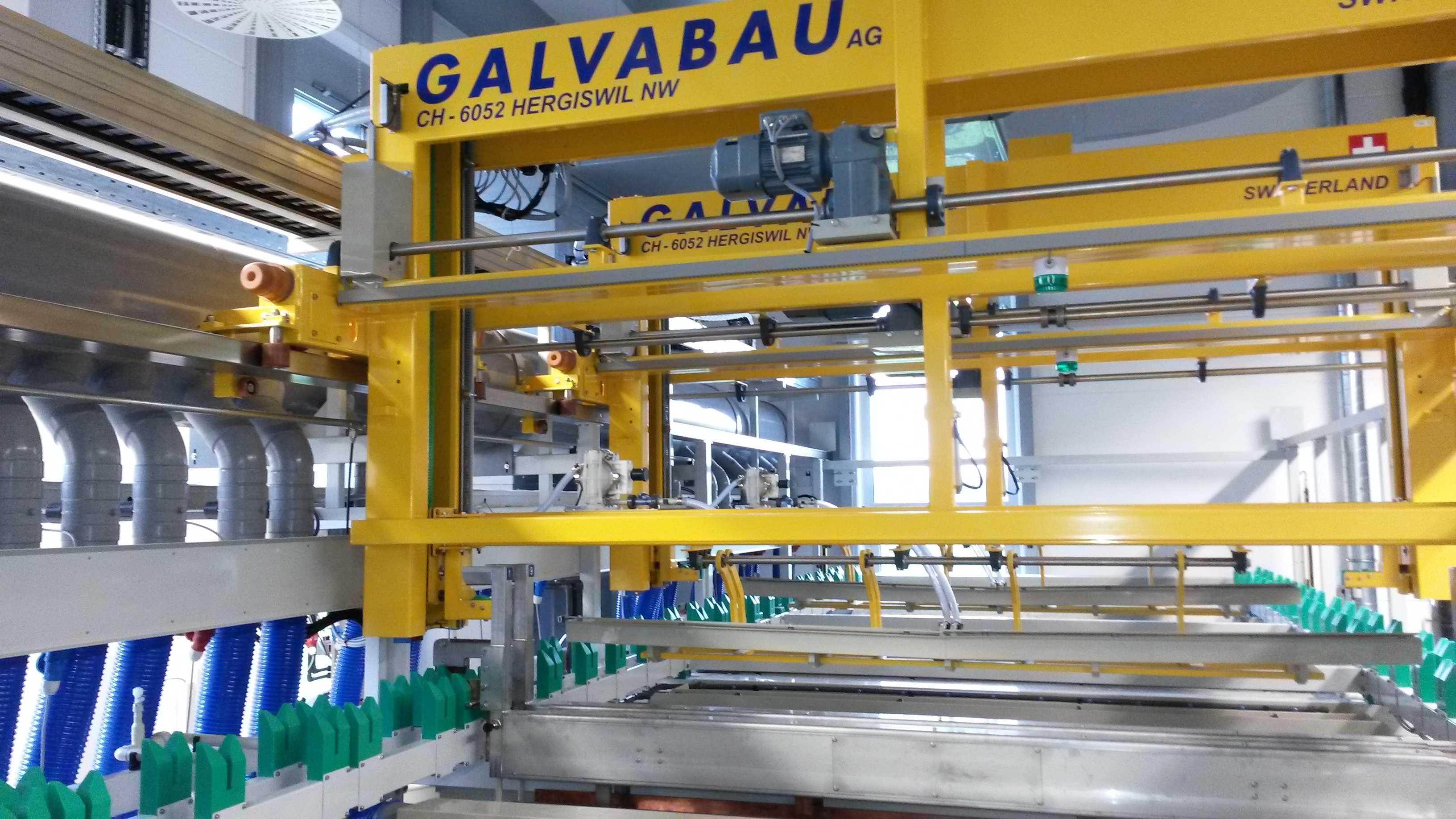

Customer

Elekonta Marek GmbH & Co.KG

ClientElekonta Marek GmbH & Co.KG

ProjectLeiterplattenautomat (DK/LBA)