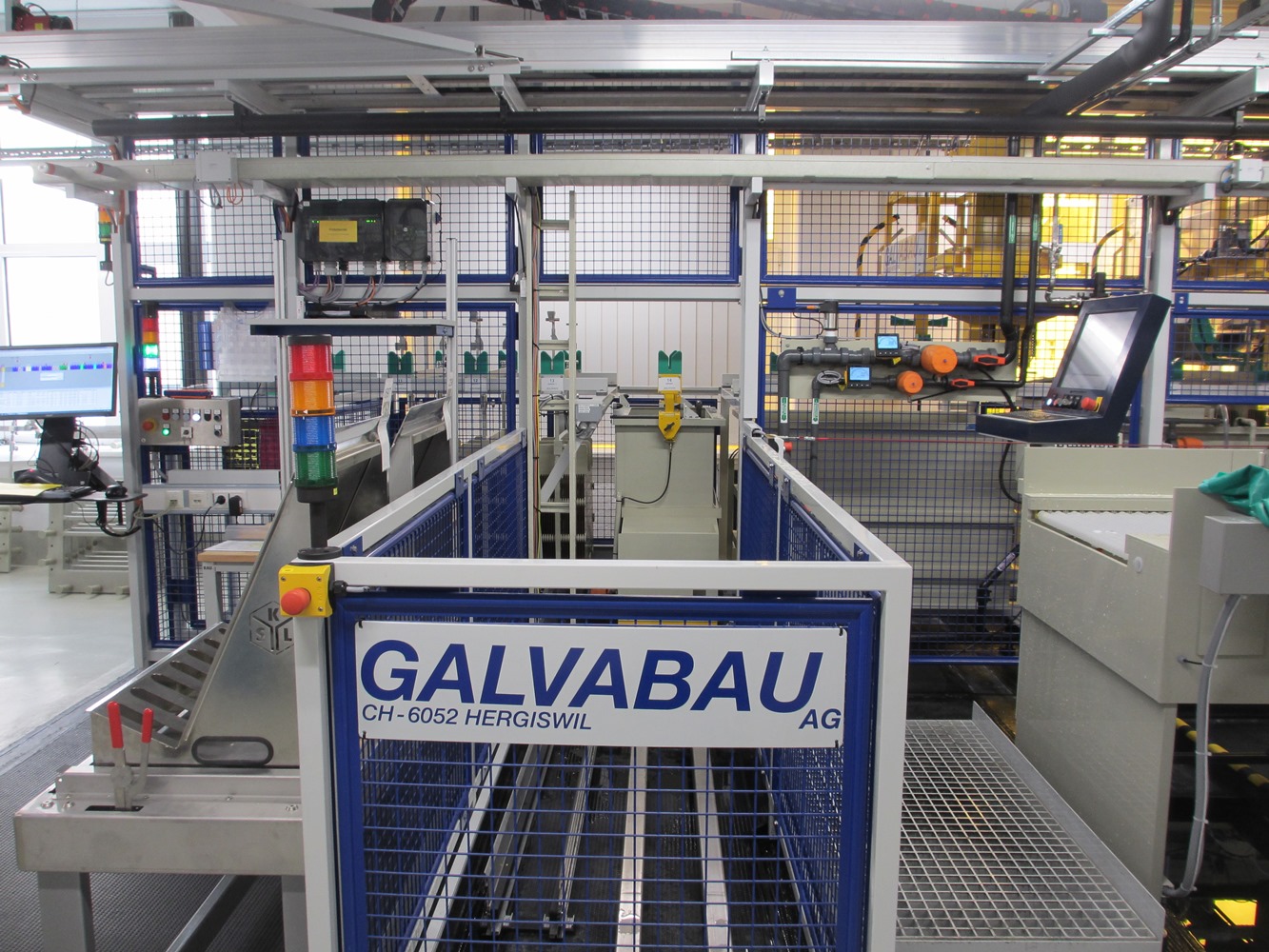

Key data

|

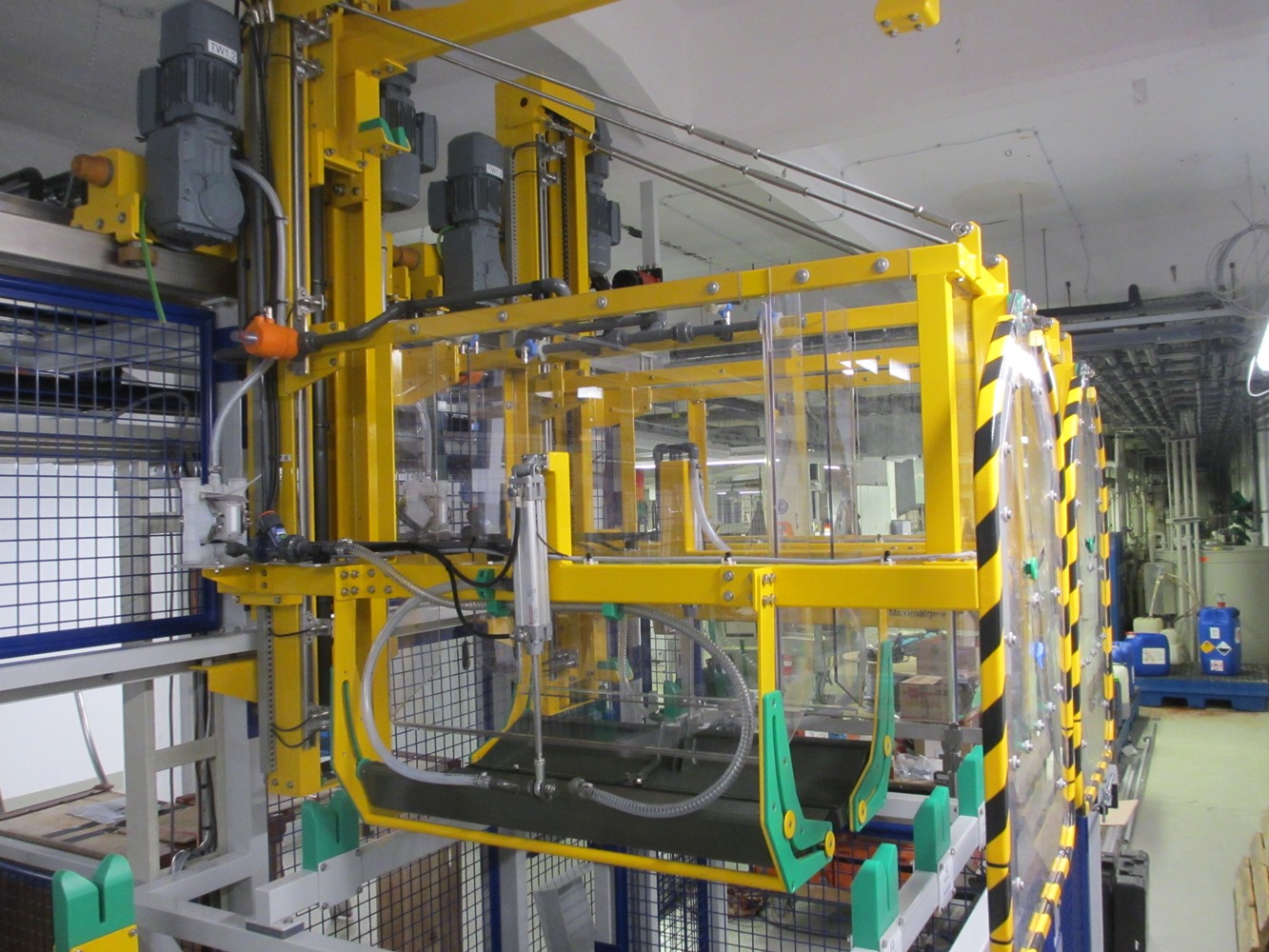

space requirements |

26 x 8,3 x 3,4 Meter |

|

construction year |

2015 |

|

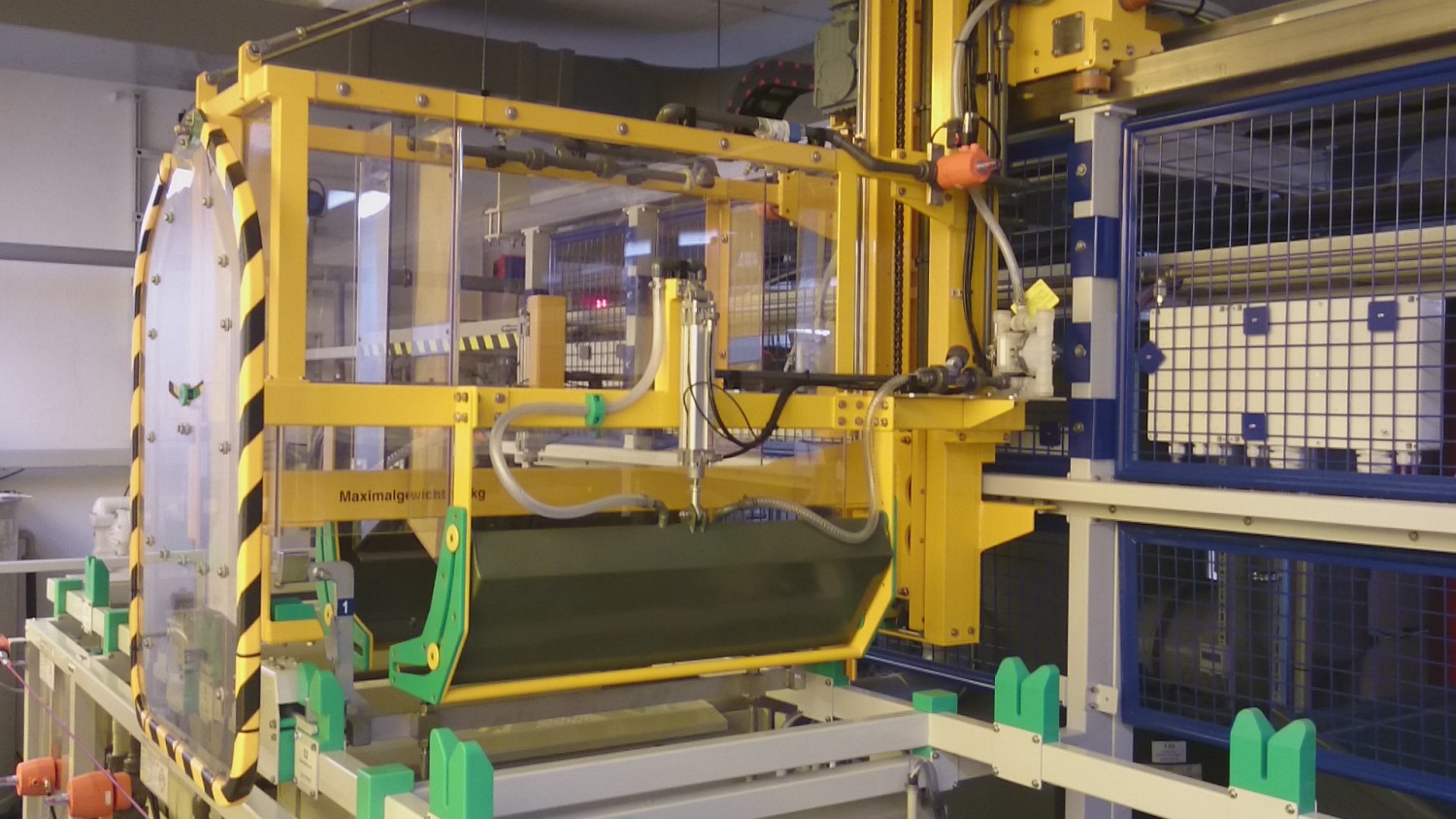

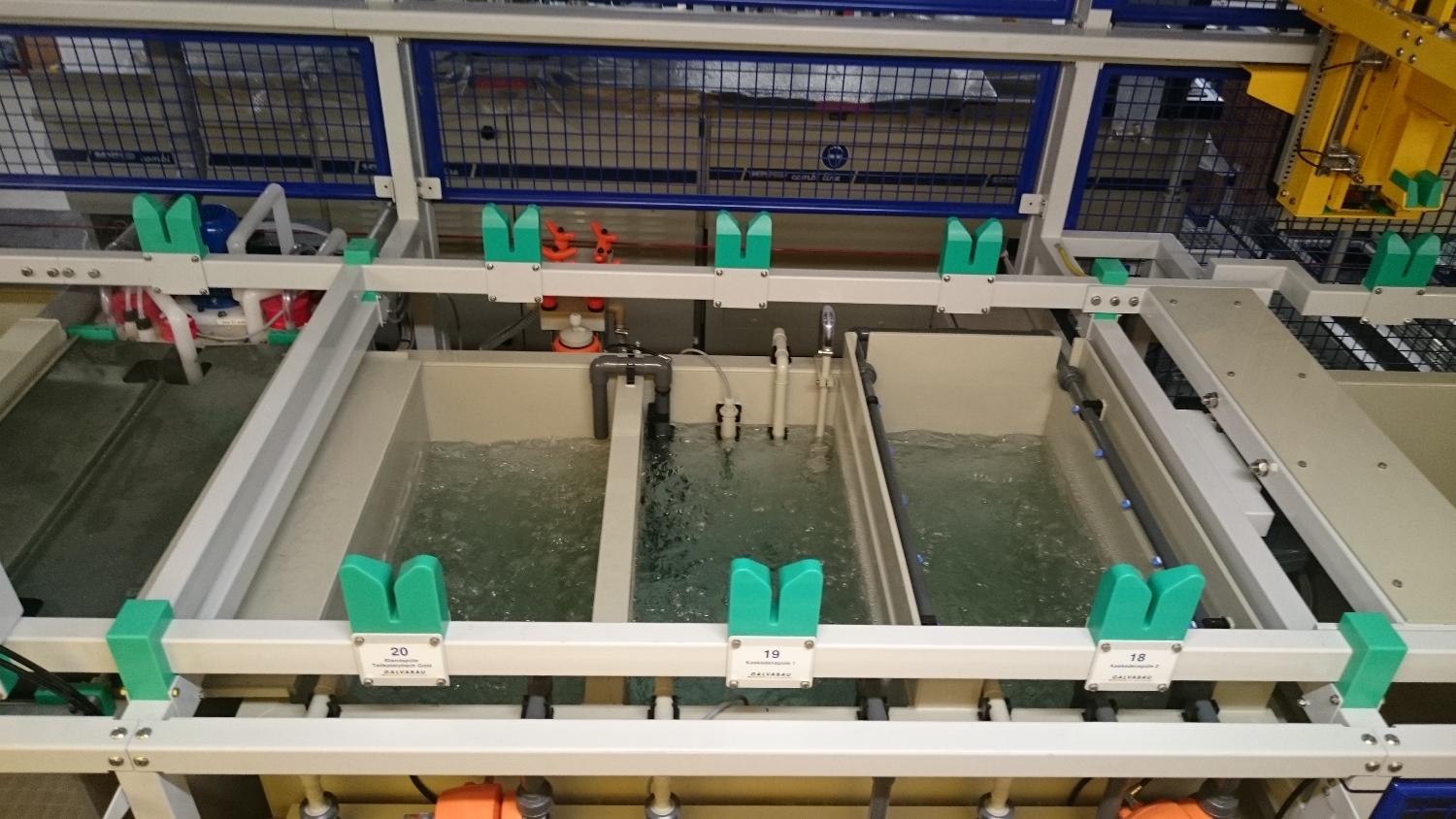

inner dimensions (rinsing tank) |

410 x 890 x 890 mm |

|

capacity |

12 min |

Customer

KSG Leiterplatten GmbH

ClientKSG Leiterplatten GnbH

Project chem. Ni-Pd-Au Automat